-

Hydro Turbines

-

Parts & Accesories

-

React Solar Pumps

-

React Pump Info

-

Dealer Products

-

Dealer Documents

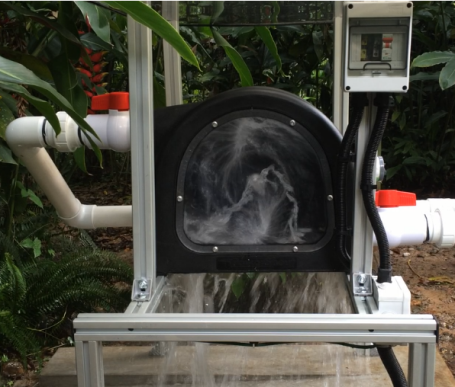

Great new just in from Florin:

Hi Michael,

PLT80 is online now… this is amazing….we got 850W from a site with 68m head and 2L/sec.

We did expect only 600W but we got a little more head. Pictures & video

Let's use the calculation tool to rerun the numbers to determine what the efficiency must be.

Both the head and the flow must have increased relative to the original design.

Click here for the original site data. Note 2 x 6.7mm jets were fitted at the factory.

If we now force the dynamic head to be 67m by making the pipe large (so there is no friction head loss) and insert 67m for the head (from 60m) we will find that the jet sizes have been automatically reduced to 6.5mm for the 2l/s flow. Now if we increase the flow rate from 2 to 2.2l/s (so that the jets sizes are correct again) then we calculate 748W before cable and MPPT losses. Click here for the revised site data.

With the cable loss we have 705W and if we assume 4% MPPT loss then we would expect to see 677W on the MC250 display.

But as you can see we got 850W on the MC250 display, which is 941W approx. at the turbine (after allowing for cable and MPPT losses).

So the turbine efficiency at this site = 941/(67 x 2.2 x 9.81) = 65% ! (80% on both PMA and Pelton rotor)

The hydro system efficiency (including wire/controller) is = 850/(67 x 2.2 x 9.81) = 58%.

Continue reading